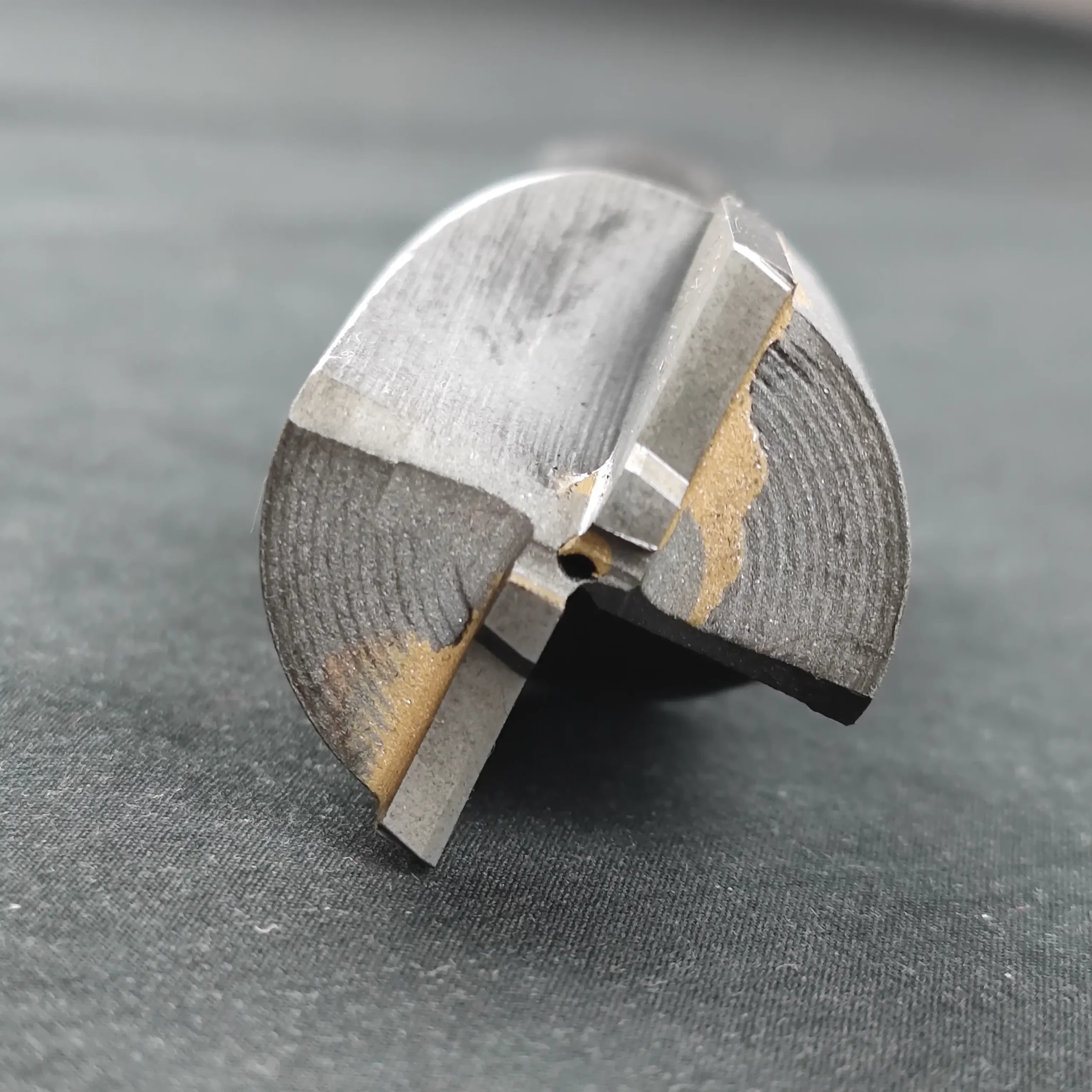

Non-standard forming tools are specialized cutting tools designed to meet specific processing needs that cannot be addressed by standard tools. These custom tools are crucial in various industries such as aerospace, automotive, medical devices, and electronics, where unique shapes, dimensions, and high-precision requirements are common.

Key Features:

- Custom Design: Tailored to specific application requirements, ensuring optimal performance and precision.

- High-Quality Materials: Constructed from durable materials like carbide, high-speed steel (HSS), and polycrystalline diamond (PCD) to enhance tool life and performance.

- Advanced Coatings: Available with specialized coatings such as TiN, TiAlN, and diamond to improve wear resistance and reduce friction.

- Versatile Applications: Suitable for a wide range of materials including metals, composites, and plastics.

- Enhanced Efficiency: Designed to optimize production processes, reduce cycle times, and minimize the need for secondary operations.

Benefits:

- Precision and Accuracy: Achieves high precision in complex geometries, ensuring superior product quality.

- Customization: Fully customizable to meet unique requirements, providing flexibility in design and application.

- Improved Productivity: Enhances machining efficiency and reduces production costs by minimizing downtime and secondary processing.

- Extended Tool Life: High-quality materials and coatings increase tool durability, reducing the frequency of replacements.